Foundries

Chemical Tank Farm

Control House has recently completed the third stage of an ongoing project to monitor and automate our client’s raw material & end product storage facilities’. In addition to their own factory based storage, this is being extended to monitor their customers’ storage tanks enabling timely deliveries without the need for their customer having to request the deliveries as they automatically arrive just in time. This allows our client to optimise their transport and production facilities with real time data.

Chemically Bonded Sand System

Control House together with their customer Eurotek Foundry Products have continued to develop these systems to maintain their position as the premium, Chemically Bonded Sand Control System, on the market.

Heat Treatment

Control House has recently installed upgrades to a system we originally installed in 2006.

The initial project was to develop a PC based SCADA (Supervisory Control and Data Acquisition) system for a large heat treatment operation in London.

‘HEAT TREAT Buddy’ was developed to provide all the sophisticated control required in the very stringent Aerospace sector. ‘HEAT TREAT Buddy’ controls the furnace temperatures & ramp rates within the necessary tolerances and plots dynamic graphs with easy to use zoom & pan functionality.

Benefits

The project enabled the company to meet the stringent requirements for Aerospace contracts to NADCAP and the Aerospace Material Specifications AMS 2750D.

The quality managers, production managers & operators have all benefited from the simple to use interface which has been designed to minimise human error, speed up the operating procedure & improve the quality of the heat treatment process.

Information for regular audits is now readily available and managed in a secure, tamper-proof data base.

Multiple runs can be scheduled to be started without supervision when staff are not on site, maximising the throughput & efficiency of the whole facility.

Control System for a new foundry in Denmark

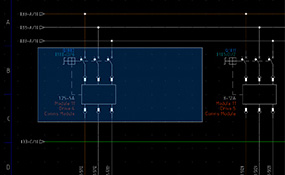

Control House developed and commissioned an integrated control system for a brand new state of the art foundry installation in Denmark.

Comprising

- Chemically bonded sand mixing

- Mould Handling - Carousels, Rollover units and automated casting tracks

- Sand reclamation - Cooling & transportation

Benefits

After the system was commissioned, the client stopped subcontracting significant parts of their work giving them greater control over production whilst maximising profitability. They also won new work which they would never have secured without this facility.

Control System to upgrade existing foundry machinery

A similar integrated control system was installed in Southampton on existing machinery that was in need of automation.

Benefits

Prior to the new controls being installed, production was frustrated by bottlenecks caused by poor design and outdated methods of operation. Following in depth consultations with the client, the problem areas were successfully addressed proving to be a great investment due to much greater operational efficiency & reduced scrap product.

Innovative products

Latest news

If you would like more information on our Products & Services, please contact us in your preferred way.

- +44 (0)1422 32 75 32

- info@controlhouse.co.uk